The global shrimp aquaculture industry is undergoing a transformative phase driven by innovations that

enhance productivity, biosecurity, and sustainability. Among these innovations, the shrimp nursery system has emerged as a strategic and flexible tool, enabling farmers to improve survival rates, manage farm inputs, and mitigate risks. Acting as an intermediary stage between hatchery-reared post larvae (PL) and grow-out ponds, nurseries offer a host of operational advantages that traditional direct grow-out stocking systems often lack.

The concept of a shrimp nursery

A shrimp nursery is a dedicated rearing facility—either indoor or outdoor—designed to hold and grow shrimp post larvae (PL) for 25 to 30 days before transferring them to grow-out ponds. The nursery similar to the shrimp grow-out pond has seen various evolutions in terms of structural design and operational principal.

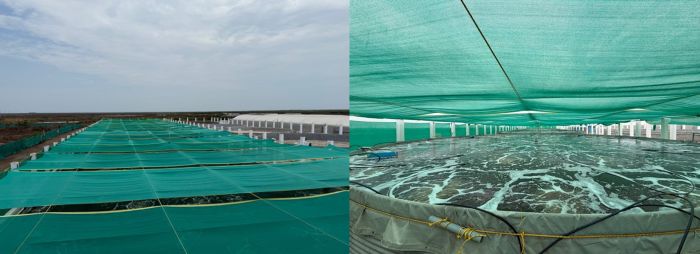

In the early days, nurseries were traditionally large ponds in open systems. Gradually, they have evolved into closed indoor systems. The design of nursery tanks can be round, rectangular or raceway type and can be located indoor or outdoor. These nurseries may use cement or plastic tanks, lined raceways, or HDPE-lined earthen ponds, shaded or covered with nets or greenhouse, depending on infrastructure, climate, and investment level.

Stocking densities in nurseries typically range from 1,000 to 10,000 PL/m³, with controlled facilities for aeration, automation, water exchange as well as, feed and health management to produce robust post larvae.

The concept of shrimp nursery goes way back to the 1970s; since then it has been a part of the shrimp production system globally. Shrimp nurseries are more popular in Latin American Growing PL 8-10 in MAPL multiphase nursery facility between 0.25g to 0.50g depending on the genetics is part of the strategy for a steady success rate and healthy economic returns. shrimp producing countries. Only recently, they have gained attention in Asia due to prevalence of disease and high crop failure rates.

The strategic value of shrimp nurseries

The value of shrimp nursery is more than just a rearing facility. They are a flexible operational tool that allows farmers to benefit from better screening and health management. Nurseries serve as a bio-secure buffer between hatcheries and ponds; it enables early detection of disease symptoms, allowing for timely treatment and removal of unhealthy individuals before reaching grow-out ponds. This reduces or eliminates the risk of pathogen introduction in the grow-out ponds as various visual observations and diagnostic tests can be performed on the post larvae during the nursery phase which gives a safety cushion to avoid large disease outbreaks in grow-out ponds.

Proper acclimatisation

The controlled environment allows farmers to acclimatise shrimp to pond water conditions, hence reducing stress and mortality. The nursery concept is a perfect tool, allows for farming shrimp in low salinity farming areas. We know that any drop in salinity creates stress to post larvae.

In addition to that, if a farmer has many ponds with varying salinities, a nursery can act as a perfect intermediate allowing shrimp post larvae to acclimatise and condition properly to avoid stress and mortality.

Control over health management of post larvae Shrimp transferred from nurseries to grow-out ponds are typically more robust and they feed actively. They adapt faster to pond environments and show better feed conversion ratio (FCR), optimal feeding rate, better size uniformity and better response to various physico-chemical stressors in the pond environment.

This can be attributed to targeted treatment such as with the use of probiotics, bioactive compounds, immunostimulants and high-quality nursery feed during the rearing period. Incorporation of concepts like biofloc and recirculating aquaculture system (RAS) also further improves the post larvae’s robustness.

Flexible stocking and harvesting schedule

By using nurseries, farmers can stock their grow-out ponds in phases rather than all at once. This approach reduces the workload at any one time; it optimises feed and energy usage, and allows harvests to be scheduled more predictably, aligning with peak market prices. This flexibility enhances economic efficiency and cash flow management.

Integrated multiphase approach

Multiphase farming involves dividing the production cycle into several stages, each with optimised environments and production goal objectives. A typical three-phase system comprises: hatchery to nursery stage, nursery to transition or pre grow-out stage (e.g. raceways) and final grow out stage.

This operational system improves input efficiency, resource allocation, and production forecasting, making it highly adaptable to both small-scale and commercial operations.

MAPL multiphase shrimp farming model

The multiphase shrimp rearing facility by Mayank Aquaculture Pvt. Ltd. (MAPL) is the first of its kind isolated nursery facility in Gujarat, India. Its concept differs from the conventional or traditional nursery rearing as it is in an isolated area away from shrimp farming operations. The prime reason for this is the congestion in the shrimp farming area; the creek water source poses risk of pathogen introduction and cross contamination to the traditional nursery systems.

Secondly, the sophisticated infrastructure and design modifications can compromise the culture area and more importantly difficult to amend at every shrimp farming site of MAPL across the regions.. Figure 1 shows the project overview

This state-of-the-art facility involves indoor and outdoor nursery rearing, with 50-tonnes capacity indoor tanks and 200-tonnes capacity outdoor tanks. The incorporation of a seven-step water treatment ensures a disease-free water source to eliminate the risk of contamination to post larvae. The water undergoes settlement, storage in reservoir, rapid sand filter, slow sand filter, cartridge filter, ozoniser and UV treatment (Figure 2).

The rearing of PL 8-10 is carried out in the nursery facility until it reaches PL 30 to 40. The post larvae usually weigh around 3 to 4mg initially and final body weight after rearing is between 0.25g to 0.50g depending on the genetics, stocking density at the target grow-out pond and production goals.

Two approaches in post larvae rearing

These are as follows:

- Rearing of post larvae from PL 5-6 to PL 15 at phase 1 at around stocking density of 8 to 10 PL/L and then later shifting the PL 15 to outdoor tanks at stocking density of 4 to 5 PL/L where they are reared for an additional 20 to 25 days and then transferred at PL 35 to 40 to the grow out ponds.

- The shrimp post larvae which are typically PL 8 are stocked for 22 to 30 days in outdoor nursery tanks around 5 to 6 PL/L before transferring to grow-out ponds. Sometimes, even younger post larvae at around PL 5 or PL 6 are utilised as more PLs can be packed into each bag (4,000 to 4,500 ) instead of the conventional 3,000 to 3,300 PLs per bag for PL 8 to 10

Additionally, this also reduces the freight cost per post larvae with more per cargo. It is important to get early post larvae as in our region the cost of Litopenaeus vannamei post larvae is USD 5.84/1,000 PLs or INR 0.50/PL. This helps in reducing the price of post larvae by 20 to 25%.

The incorporation of biofloc technology has benefited the operations in terms of maintaining zero to minimal water exchange system at definitive periods and also boosting the health status of the shrimp. The shrimp are transported in a truck with plastic tanks and continuous oxygenation and also by following other SOPs pertaining to the transfer of nursery reared post larvae. Usually these have stunted growth and once they enter the grow-out pond, they exhibit compensatory growth as they reach optimal conditions and optimal feeding.

Benefits of isolated multiphase nursery rearing

These include:

• Proper post larvae screening and health management.

• Salinity acclimatisation for better survival.

• Reduction in days of culture gives an opportunity to save feed, energy cost and increase or double the production giving better economies of scale.

• Better average daily growth (ADG) post compensatory growth (direct stocking of post larvae at ADG 0.23g versus nursery reared ADG at 0.29g). Even combining nursery + grow-out stage rearing the average benefit with ADG post compensatory growth is around 8 to 10% with more efficient FCR and survival increase by 10 to 15%. This varies with genetics, stocking density, farming management and days of culture.

• Helps in combating summer stress (effect on ammonia, nitrite and Vibrio spp.), white gut, white faecal disease and running mortality syndrome very efficiently.

• Stocking post larvae in nursery tanks to effectively manage crop planning in batches and maintain proper production output as per market trends and also maintain positive cash flow management.

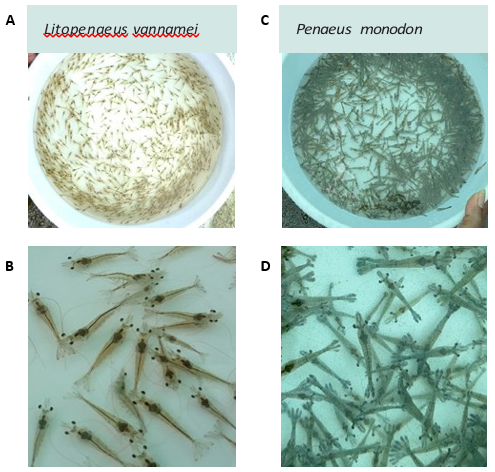

• Switching between Penaeus monodon and L. vannamei becomes very flexible from stocking until harvest and production goals, as after August, the domestic demand for vannamei is good in the West Indian market.

• Reduction in days of culture helps the shrimp to reach marketable size before white spot syndrome virus (WSSV) outbreak (10 to 12g for vannamei, 33 to 40g for black tiger). Figure 3 shows the post larvae rearing for both species.

Dependent on shrimp genetic line

If a shrimp genetic line has a higher ADG, above 0.30g, it is still advisable to apply direct stocking, on condition that the farmer can handle the physico-chemical stress, Vibrio spp., organic load, proper water treatment, water conditioning protocols, higher survival rates above 75% and good success rate at every crop.

However, all the above requirements are not achievable by everyone, as is evident from the disease issues and failure rate surrounding farms in Asia. Fulfilling all these criteria is possible but still the question remains – “Production at What Cost” as success rate and selling price ultimately is the decision maker.

Our experience showed that even for faster specific pathogen free (SPF) genetics in our region, with PL 8, we have seen a growth of 2.5g to 3g in 30 days post stocking. However, if we adopt an approach of bringing PL 5 and rearing them to PL 15 and then stocking into grow-out ponds, we have seen shrimp reaching 4g to 4.5g in 30 days, depending on the genetic line.

Additionally, with weekly moulting frequency in juvenile shrimp, we have seen increases in growth up to 35 to 37% in average body weight. (direct stocking of post larvae at 10.25g versus PL 15 nursery-reared at 14g). This has also helped MAPL’s domestic market operations in terms of producing cost effective post larvae.

By stocking younger post larvae (PL5), we reduce seed factor cost, i.e. 20-25% while the additional stocking of PL 15 gives better growth and survival that reflects on cost of production/kg of seed at the final stage. We have consistent success rate, is profitable at small sizes (10-16g) and adopt a batch wise stocking model.

“The nursery concept is very good for low to medium ADG shrimp genetics which aim for compensatory growth post stocking in grow-out ponds.”

New SPF black tiger genetics

In the new SPF black tiger genetics, we have also seen that stocking post larvae in nursery tanks for 10 to 15 days as an acclimatisation step to low salinity grow-out ponds of around 15 ppt, gave encouraging results by boosting shrimp health status and immunity. The result has been better growth, an 8-10% increase in ADG and a steady survival rate at farm.

From our experience, the nursery concept is very good for low to medium ADG shrimp genetics which aim for compensatory growth post stocking in grow-out ponds. For those from fast genetics resulting in higher ADGs one can still think of acclimatisation, health status and screening to maintain success rate at farms. It is evident that using nurseries have helped the corporate and large-scale operation in Latin America and Ecuador, deliver success rates and utilise their genetics efficiently.

India vs Ecuador

Comparing India and Ecuador, the concept and purpose of nursery are slightly different. In Ecuador with higher success rates in farming, nurseries are for operational management. While in India and the rest of Asia where success rates are low, the nursery concept is more for biosecurity and disease mitigation.

Hence, the cost of nursery setup can be high for Asia given that water filtration and treatment add cost. However, if nurseries are working for Latin America they should also work for Asia, but the intended use should be clearly defined for the farmer or corporate firm.

More importantly, for small scale farmers in India, it would be advisable to set up farmer cluster group and share cost for high quality nursery setups.

Lastly, however nursery is not the solution for every problem, but one can see it as a “PAL” Pre-grow assistant for post larvae or “PARTNER” Precision Aquaculture Rearing Technology for Nurturing & Enhanced Returns that holds the capability to give healthy shrimp and healthy economic returns with steady success rate.

This article was first published in July/August 2025.