Innovation that protects

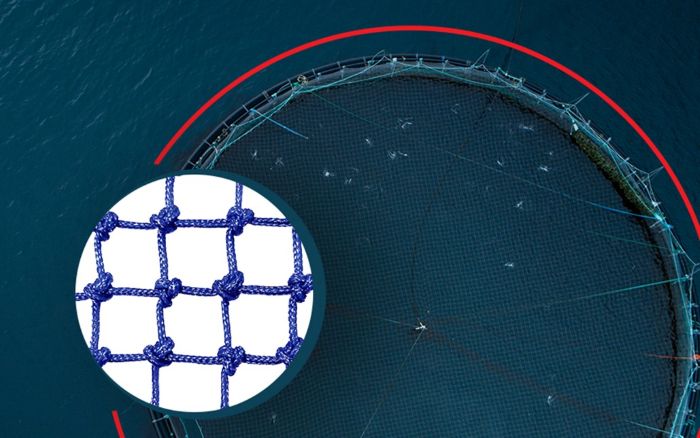

Garware Technical Fibres continues to push the boundaries of innovation in aquaculture, offering solutions designed to address the specific challenges of each operation. Their multidisciplinary team—made up of specialists in materials and blends, as well as experts in polymers and technical fibres—works to deliver high-tech products aimed at maximizing efficiency and safety in farming centers.

“We know that no two production strategies are alike. We develop a wide range of nets tailored to every need: nets for in-situ washing, knotted or knotless, suitable for antifouling coating, recyclable, and even equipped with communication and reporting technology. What they all share is a long service life, high manufacturing standards, and a design that stems from actively listening to our clients. The key behind these solutions is reducing costs, minimizing risks, and improving production performance. For Garware, the customer’s voice is essential, understanding their requirements and how they approach their operations. We then combine this with applied science, material definition, and net construction,”

says Francisco Serra, Commercial Manager of Garware Technical Fibres Chile.

New generations of nets

CFR, whose composite-core construction ensures uniform shape, greater strength, and reduced weight, making it both durable and efficient. It offers excellent cut resistance and high mesh rigidity for enhanced safety. S.CFR is its 100% recyclable version.

In the case of predator-control nets, we offer products designed to stop sea lion attacks through three key variables that effectively limit the access of these predators: tensile strength, cut resistance, and net rigidity. The combination of these three factors has led to significant reductions in attacks on farming sites.

“Within the predator-control product line, we highlight the success that SUC MBX and X18 have had in Chile. SUC MBX is Garware’s most widely used product in the industry. Much of its success is due to the presence of stainless-steel strands in its core. SUC MBX has been used primarily in designs with overhead predator protection, while X18 has been used in drop-down configurations,”

says Marcos Jofré, Business Associate at Garware Technical Fibres Chile.

Pro Max is the evolution of X18, offering greater rigidity and improved abrasion resistance. Safemax is the evolution of SUC MBX, with the same tensile strength but a smaller diameter and no stainless-steel strands—surpassing its cut resistance and delivering even greater tensile strength with a reduced diameter. Another important feature of Safemax, compared with SUC MBX, is its increased rigidity, allowing it to be used both in traditional predator-control models and in vertical-drop or drop-down designs. And ACE meets all the previous characteristics and is also a predator-control net designed for exposed sites. Its reduced diameter provides low resistance to current pressure.

As salmon farming operations expand and face more challenging environments, the choice of efficient, safe, and sustainable materials becomes critical.